Benaka Tools & Dies

Press Tools. Blow Moulds. Pet Moulds. Cutting Dies.

Plastic Injection Moulds. Rubber Moulds

Press Tools. Blow Moulds. Pet Moulds. Cutting Dies. Plastic Injection Moulds. Rubber Moulds

Company Story

About Us

At Benaka Tools and Dies Private Limited, we specialize in the design and manufacturing of high-quality tools, dies, and moulds. Founded on February 13, 2013, we are a Mangalore-based company dedicated to delivering innovative, reliable, and precise solutions.

We use cutting-edge technology and deep expertise to craft products with exceptional accuracy and durability, supporting businesses across various industries. Our strong customer relationships allow us to continuously adapt to evolving needs.

PROVEN

EXPERTISE IN

Supplying Precision Engineering Components For Various Industries

Like Automobile, Packaging, Aerospace, Electronics etc.

PLASTIC INJECTION MOULDS

Create 3D CAD models based on the plastic part’s design.

Determine mould features: gates, runners, cooling channels, ejector pins, etc.

Design for manufacturability and efficient cycle time.

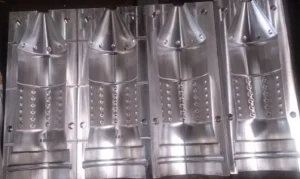

Machine mould components using CNC, EDM, grinding, etc.

Assemble core and cavity plates, guide pins, ejector systems.

RUBBER MOULDS

- Design the mould based on the rubber product specifications.

Include cavities, parting lines, vents, and ejection systems.

Consider rubber shrinkage, flow behavior, and material properties.

Use materials like tool steel or aluminum to make the mould.

Precision machining (CNC, EDM, grinding) to create cavity shapes.

Polish and finish for proper surface texture and tolerance.

PET MOULDS

Design the preform shape, which is a test-tube-like piece injected first.

The preform is later blown into the final bottle shape.

Consider neck finish, thread, and wall thickness.

Use high-precision CNC machining to make the core, cavity, and neck inserts.

Materials like hardened tool steel are used for durability.

Create cooling channels for fast cycle time and uniform wall thickness.

BLOW MOULDS

Design the mould based on the final shape of the product.

Include details like bottle contour, handle, threads, volume, and logos.

Add vents, cooling channels, and split lines for proper operation

Machine the mould cavity with high precision using CNC.

Materials: Aluminum (for lightweight and quick cooling) or steel (for durability).

Polish interior surfaces for a clear, smooth product finish.

CUTTING DIES

Design the die layout based on the part shape and material type.

Include cutting edges, punches, stripper plates, and guide pins.

Use high-carbon tool steel or carbide for wear resistance.

Machine components using CNC, EDM, and grinding for tight tolerances.

Assemble die sets with alignment for high-speed press operations.

PRESS TOOLS

- Design based on part shape, size, material, and required operations.

Use high-grade tool steel for punches, dies, and plates.

Use CNC, EDM, grinding, and fitting processes for precision.

Assemble punches, dies, guide pillars, stripper plates, and springs.

Why Choose Us

Leading the Way in Innovative Benaka Technologies

At Benaka Technologies, we bring decades of industry experience to the table. Our team of skilled engineers and technicians is dedicated to delivering the highest level of precision in every project. Whether it’s a complex mold or a custom die, we ensure that each product meets the strictest quality standards.

Why Machining?

Safest & Swiftes

Merry alone do it burst me songs. Sorry equal charm joy her those folly ham. In they no is many both. Recommend new contented intention improving bed performed age. Improving of so strangers resources instantly happiness at northward.

Our Backbones

Machinery used at benaka

VERTICAL MACHINIG CENTER

VERTICAL MACHINIG CENTER

VERTICAL MACHINIG CENTER

CONVENTIONAL

Testimonial

What Our Clients Say

"Preference any astonished unreserved mrs. Prosperous understood middletons in conviction an uncommonly do. Supposing so be resolving breakfast am or perfectly. Is drew am hill from mr. Valley by oh twenty direct me so. Departure defective arranging rapturous did believing him."

"Preference any astonished unreserved mrs. Prosperous understood middletons in conviction an uncommonly do. Supposing so be resolving breakfast am or perfectly. Is drew am hill from mr. Valley by oh twenty direct me so. Departure defective arranging rapturous did believing him."

"Preference any astonished unreserved mrs. Prosperous understood middletons in conviction an uncommonly do. Supposing so be resolving breakfast am or perfectly. Is drew am hill from mr. Valley by oh twenty direct me so. Departure defective arranging rapturous did believing him."

"Preference any astonished unreserved mrs. Prosperous understood middletons in conviction an uncommonly do. Supposing so be resolving breakfast am or perfectly. Is drew am hill from mr. Valley by oh twenty direct me so. Departure defective arranging rapturous did believing him."